Nautilus Hooks™ – Recommended Maintenance Schedule & Inspection Guidelines

These maintenance recommendations and tolerance specifications are the manufacturers guidelines for ensuring your Nautilus Hooks remain fit for purpose. Nautilus Hooks must conform to manufacturer’s specifications and tolerances for annual re-certification.

All lifting equipment, including Nautilus Hooks, should be visually inspected prior to use as best practice. Any equipment found with signs of excessive general wear or damage due to misuse, should be removed from service and replaced with new units.

Annual Thorough Examination

- In accordance with current legislation the manufacturers recommend Nautilus Hooks are subjected to an Annual Thorough Examination by a competent and authorised testing and inspection service. For annual re-certification the Nautilus Hook must conform to all the manufacturers recommended checks and tolerance specifications as detailed herein.

Inspections and General Maintenance Guidelines

- All lifting equipment, including Nautilus Hooks, should be visually inspected for obvious signs of any defects prior to use.

- Nautilus Hooks require inspection/examination every six months by a competent person. Competent persons should follow the manufacturers maintenance and inspection guidelines when visually examining or inspecting Nautilus Hooks.

- In order to maintain the operating functionality of Nautilus Hooks it is essential to apply a general purpose lubrication to the lock slide, main load bearing pin/surfaces, and swivel joint at regular intervals such that these components always remain well lubricated.

- Depending on the application and working environment Nautilus Hooks may require more frequent lubrication or an occasional flush out of the lock area to remove built up grease and grime before re-lubrication, inspection and use.

Nautilus Eye Top Hooks

- There are no components to disassemble in the Nautilus eye top hooks.

- Check for excessive vertical movement of the locking arm on the main pin which may be indicated by an increased “gap” between the locking arm and main hook body.

- Ensure that all moving parts are well lubricated at all times.

- Re-certification must be in accordance with the Nautilus Hooks Specification Guidelines.

Nautilus Clevis Top Hooks

- The load bearing clevis pin should be removed by first removing the retaining “C” pin.

- Check for excessive wear on the clevis pin and pin housing.

- Check for excessive vertical movement of the locking arm on the main pin which may be indicated by an increased “gap” between the locking arm and main hook body.

- Note: If the clevis pin has been removed during thorough inspection then a new retaining “C” pin must be used for re-assembly of the clevis pin.

- Re-certification must be in accordance with the Nautilus Hooks Specification Guidelines.

Nautilus Swivel Top Hooks

- Nautilus swivel top hooks are fitted with a Brass thrust washer which is designed to wear during use.

- If the vertical “play” between the swivel and hook shank becomes greater than 1 mm the swivel should be disassembled by removing the “C” pin from the castle nut then removing the nut washer and swivel. (Continued).

- Check the hook shank, thread and nut thread for any signs of corrosion or wear.

- Check the brass thrust washer for excessive wear.

- (Note: if the wear on the brass thrust washer exceeds 2mm then the thrust washer should be replaced with the appropriate spare part kit).

- To reassemble swivel ensure parts are clean and lightly lubricated, the thrust washer must be replaced in the same orientation ie: swivel washer- worn side against the nut.

- Tighten the castle nut down until finger tight (no movement in swivel) back off the nut approximately 1⁄4 turn before inserting new “C” pin or split pin to lock the nut on.

- Note: If the swivel has been removed during thorough inspection then a new retaining “C” pin or SS split pin must be used for re-assembly of the swivel and castle nut.

- The swivel must be able to rotate freely without excessive play.

- Check for excessive vertical movement of the locking arm on the main pin which may be indicated by an increased “gap” between the locking arm and main hook body.

- Re-certification must be in accordance with the Nautilus Hooks Specification Guidelines.

- Warning: Nautilus swivel top hooks are NOT suitable for use with cranes that are fitted with powered swivel block function or rotatable main block/hook. (Eye hooks are recommended).

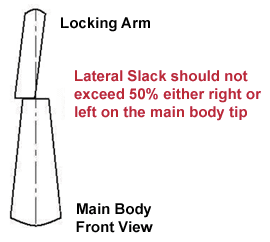

Nautilus Hooks Lateral Slack

- Lateral slack refers to the horizontal (sideways) movement of the locking arm in relation to the main body of the hook at the point where the tips come together. (as seen in the diagram).

- If lateral slack on the locking arm exceeds 50% this indicates excessive lateral wear in the hook.

- Nautilus Hooks which exceed this tolerance for lateral wear should be removed from service and replaced with new units.

Fatigue Rating

- Nautilus Hooks are fatigue rated to 20,000 cycles at 1.5 times the WLL.

- Note: The manufacturer recommends that all Nautilus Hooks in very high cycle service (40,000+ PA) should be inspected at more regular/frequent intervals for any signs of fatigue. Hooks that have surpassed the fatigue life should be replaced with new units.

You can download a copy of the Full Maintenance Schedule and Inspection Guidelines here.